Time and date

CONSTRUCTION DIRECTORY

Moore Concrete Products Ltd Contact Details

Address

41 Woodside Road

Ballymena

County Antrim

BT42 4QH

Northern Ireland

Opening Hours

Thursday

08:00 am-05:00 pm

Monday

08:00 am-05:00 pm

Tuesday

08:00 am-05:00 pm

Wednesday

08:00 am-05:00 pm

Thursday

08:00 am-05:00 pm

Friday

08:00 am-05:00 pm

Saturday

Closed

Sunday

Closed

Other Dates

About Moore Concrete Products Ltd

Moore Concrete Products Ltd. supplies high quality precast products to the civil engineering, building and agricultural sectors. Moore Concrete have been involved in numerous prestigious award winning projects throughout the UK and Ireland.

Our Ethos

Drawing on 40 years experience, coupled with an ethos of continued investment the company has grown into a leading precaster with a reputation for innovation, dependability, quality and product development. Moore Concrete adopts a customer-led strategy, working closely with contractors, farmers and local universities, to ensure innovation is used to provide customers with the best solutions possible for their particular requirements.

'Our aim and mission is to provide our customers with quality precast solutions'

Our Ethos

Drawing on 40 years experience, coupled with an ethos of continued investment the company has grown into a leading precaster with a reputation for innovation, dependability, quality and product development. Moore Concrete adopts a customer-led strategy, working closely with contractors, farmers and local universities, to ensure innovation is used to provide customers with the best solutions possible for their particular requirements.

'Our aim and mission is to provide our customers with quality precast solutions'

Reviews & Testimonials for Moore Concrete Products Ltd

September 13, 2017

I just wanted to send a note to say how pleased I was with how the culvert job.

All parties concerned were kept up to date from design to delivery/installation, nothing was a problem and I will definitely be keeping Moore Concrete in mind for all future enquiries in which we receive.

Testimonial

by

Travis Perkins

September 13, 2017

Commented that he was pleased with the finish of the sills and the flexibility of the service when it came to deliveries.

Testimonial

by

Paul Graham - New Build

September 13, 2017

The culverts look great, thanks for your help.

Testimonial

by

Transport NI

September 12, 2017

"Robert mentioned that he was at the job where Willie Smith got the panels last month

He says they are a great panel, he said ’your panels are streets ahead of all other panels’.

Testimonial

by

Paul Harrison

September 12, 2017

'Very pleased with our recent delivery of your freestanding grain walling. Doing an excellent job of creating a bunker for the grain drier to unload into, and keeping back 300 tonnes of barley too!!'

Testimonial

by

Thomas Collins

Gallery

|

Click to close

|

Videos

News

15/10/2021

CN Awards 2021

Moore Concrete we delighted to be involved in 2 projects short listed by the prestigious Construction News Awards held at the Grosvenor House Hotel, Mayfair London on the 15th Sept 2021.

Moore Concrete manufactured precast elements for both projects in collaboration with VolkerStevin.

Fairhaven to Church Scar Coast Protection Scheme

Health, Safety and Wellbeing Excellence (Project) Highly commended:

Shortlisted Project of the Year (£20m - £50m)

Northern Ammunition Jetty in Glen Mallan

Shortlisted Project of the Year (over £50m)

Managing Director Wilbert Moore Commented "It really was a pleasure to be able to join the VolkerSlevin team on such an auspicious occasion. Although not successful in winning an award for either project on this occasion, to be recognized by the industry, through being shortlisted is a major accolade which makes me extremely proud of our contribution."

Moore Concrete manufactured precast elements for both projects in collaboration with VolkerStevin.

Fairhaven to Church Scar Coast Protection Scheme

Health, Safety and Wellbeing Excellence (Project) Highly commended:

Shortlisted Project of the Year (£20m - £50m)

Northern Ammunition Jetty in Glen Mallan

Shortlisted Project of the Year (over £50m)

Managing Director Wilbert Moore Commented "It really was a pleasure to be able to join the VolkerSlevin team on such an auspicious occasion. Although not successful in winning an award for either project on this occasion, to be recognized by the industry, through being shortlisted is a major accolade which makes me extremely proud of our contribution."

04/05/2021

QuikBloc provides a stable solution to a demolition challenge!

Moore Concrete recently supplied QuikBloc to McCormack Demolition, a company which specialises in the demolition of various projects including private housing sites to retail, industrial and commercial premises.

It is standard practice for demolition companies to put a substantial hoarding around all the sites they are working on, in order to keep the general public at a safe distance from the work that is taking place.

McCormack Demolition have been utilising QuikBloc to provide a stable attachment point for posts that support the hoarding under construction.

Moore Concrete’s Jonny McKinney was a recent visitor to a McCormack Demolition site in Belfast. Jonny explained,

“QuikBloc is the perfect block hoarding and storage solution that provides instant stability, irrespective of the prevailing ground conditions and can be re-used time after time.

“QuikBloc is an interlocking lego style block ideal for both temporary and permanent structures. When combined, the blocks create a strong structure with no need for bonding or fixing. Individual block weights range from just over 1.1t to 2.3t.

“Installation of QuikBloc is fast and simple as the blocks are manoeuvred, using the lifting anchor cast into the top of each block.

“The interlocking principle of QuikBloc provides endless flexibility as blocks can be modified or extended with ease at any time.

“As well as hoarding, QuikBloc has a variety of different uses including storage, partition walls, coastal defence and more.

It is standard practice for demolition companies to put a substantial hoarding around all the sites they are working on, in order to keep the general public at a safe distance from the work that is taking place.

McCormack Demolition have been utilising QuikBloc to provide a stable attachment point for posts that support the hoarding under construction.

Moore Concrete’s Jonny McKinney was a recent visitor to a McCormack Demolition site in Belfast. Jonny explained,

“QuikBloc is the perfect block hoarding and storage solution that provides instant stability, irrespective of the prevailing ground conditions and can be re-used time after time.

“QuikBloc is an interlocking lego style block ideal for both temporary and permanent structures. When combined, the blocks create a strong structure with no need for bonding or fixing. Individual block weights range from just over 1.1t to 2.3t.

“Installation of QuikBloc is fast and simple as the blocks are manoeuvred, using the lifting anchor cast into the top of each block.

“The interlocking principle of QuikBloc provides endless flexibility as blocks can be modified or extended with ease at any time.

“As well as hoarding, QuikBloc has a variety of different uses including storage, partition walls, coastal defence and more.

04/05/2021

Redi-Rock Ha-ha Wall

In many ways the Ha-ha wall can be described as the hidden gem of architectural landscaping, similar to the modern-day Infinity Pool. Their initial use in the UK and Ireland was championed by the 18th century landscape architect Capability Brown, who recognised their use in providing houses with this feature. The unique aspect of the Ha-ha wall is that it is sunken and therefore not visible from the house side. The base of the wall is about 1.5 metres below the natural field level and gradually slopes upwards for about 5 metres to seamlessly reach the finished field height. Livestock, therefore, approaching the wall from the field side have to descend the gradual slope to find themselves at the base. On the other hand, from the house side there is no sight whatsoever of the construction, allowing an unspoilt view of the surrounding countryside.

Thus from a practical sense, Ha-ha walls act to keep cattle and sheep out of the formal gardens, without the need for obtrusive fencing.

Fast forward three centuries, this remarkable landscaping feature has made a stunning appearance in Co Meath, following the completion of the M3 motorway. Evan Newell, the man behind the project, takes up the story:

“We had traditionally farmed 200 acres outside the village of Dunshaughlin. The construction of the new motorway meant that we lost 40-acres however the compensation available allowed us to secure an equivalent land area located on the opposite side of the motorway.”

He continued:

“But every cloud has a silver lining as our new state of affairs gave us the opportunity to build a new house, farmyard and ancillary buildings on the recently acquired property.”

Construction subsequently began on what Evan describes as a ‘passive’ house, designed to meet the most stringent environmental standards as well as being totally energy efficient. The property extends to 4,500 square feet.

“As the development of the house progressed, we wanted to ensure that an uninterrupted view of the surrounding countryside was maintained. This was the overarching factor in deciding to build a Ha-ha retaining wall.

There are two acres of lawn around the new house, which sits on a slope. We wanted the wall not only to work from an aesthetic perspective, but also as a barrier to our thoroughbred horses that would be grazing in the adjacent fields.”

The wall extends to some 200 metres in length and is 1.5 metres in height. There is an additional capping of about 15 cm of grass planted soil and this effectively provides a much more solid barrier that is significantly in excess of a standard post and railing stud farm fence that contains stock grazing land adjacent to the lawn.

“We looked at a number of construction options,” Evan confirmed.

“However, after a visit to Balmoral Show last year, I became aware of the Redi-Rock retaining wall system, manufactured by Moore Concrete. It stood out as the immediate solution.”

Redi-Rock walls comprise of a series of one tonne interlocking blocks capable of creating an instant retaining wall system that is versatile enough to achieve high structures without compromising strength.

The precast concrete units have a natural effect cobblestone appearance which creates an attractive finish. As was the case in this construction, the top block is custom designed to allow planting.

Evan Newell again

“Construction began in April this year.”

“Initially, it was a case of digging down and then adding a 6-inch covering of hardcore gravel. There was no need to put in traditional foundations as all we needed was a level surface as a base to build the wall.

The actual construction process could not have been any more straightforward. It was just like putting blocks of Lego in place.

The wall itself was completed in four days. In contrast, it took a full four weeks to complete the accompanying earth works.”

Evan concluded:

“Six months after the wall was completed, we had it fully checked over. The wall hasn’t moved a jot and it’s hardly likely to now!”

“Redi-Rock is an amazing system. It was the perfect option when it came to making the Ha-ha wall a reality.”

Evan Newell

Thus from a practical sense, Ha-ha walls act to keep cattle and sheep out of the formal gardens, without the need for obtrusive fencing.

Fast forward three centuries, this remarkable landscaping feature has made a stunning appearance in Co Meath, following the completion of the M3 motorway. Evan Newell, the man behind the project, takes up the story:

“We had traditionally farmed 200 acres outside the village of Dunshaughlin. The construction of the new motorway meant that we lost 40-acres however the compensation available allowed us to secure an equivalent land area located on the opposite side of the motorway.”

He continued:

“But every cloud has a silver lining as our new state of affairs gave us the opportunity to build a new house, farmyard and ancillary buildings on the recently acquired property.”

Construction subsequently began on what Evan describes as a ‘passive’ house, designed to meet the most stringent environmental standards as well as being totally energy efficient. The property extends to 4,500 square feet.

“As the development of the house progressed, we wanted to ensure that an uninterrupted view of the surrounding countryside was maintained. This was the overarching factor in deciding to build a Ha-ha retaining wall.

There are two acres of lawn around the new house, which sits on a slope. We wanted the wall not only to work from an aesthetic perspective, but also as a barrier to our thoroughbred horses that would be grazing in the adjacent fields.”

The wall extends to some 200 metres in length and is 1.5 metres in height. There is an additional capping of about 15 cm of grass planted soil and this effectively provides a much more solid barrier that is significantly in excess of a standard post and railing stud farm fence that contains stock grazing land adjacent to the lawn.

“We looked at a number of construction options,” Evan confirmed.

“However, after a visit to Balmoral Show last year, I became aware of the Redi-Rock retaining wall system, manufactured by Moore Concrete. It stood out as the immediate solution.”

Redi-Rock walls comprise of a series of one tonne interlocking blocks capable of creating an instant retaining wall system that is versatile enough to achieve high structures without compromising strength.

The precast concrete units have a natural effect cobblestone appearance which creates an attractive finish. As was the case in this construction, the top block is custom designed to allow planting.

Evan Newell again

“Construction began in April this year.”

“Initially, it was a case of digging down and then adding a 6-inch covering of hardcore gravel. There was no need to put in traditional foundations as all we needed was a level surface as a base to build the wall.

The actual construction process could not have been any more straightforward. It was just like putting blocks of Lego in place.

The wall itself was completed in four days. In contrast, it took a full four weeks to complete the accompanying earth works.”

Evan concluded:

“Six months after the wall was completed, we had it fully checked over. The wall hasn’t moved a jot and it’s hardly likely to now!”

“Redi-Rock is an amazing system. It was the perfect option when it came to making the Ha-ha wall a reality.”

Evan Newell

29/04/2021

Moore Concrete continues its commitment to growing apprenticeship opportunities

Ballymena-based precast concrete firm Moore Concrete continues to grow its team by appointing 6 new apprentices, bringing the company’s workforce to over 160. The appointments also mean that 11.4% of the firm’s workforce are apprentices.

The announcement was made during NI Apprenticeship Week – a DfE initiative designed to raise the profile of apprenticeships across Northern Ireland.

Aine Carey, HR Coordinator of Moore Concrete, said, “We are very pleased to be making this positive announcement during Apprenticeship Week. Moore Concrete has been a long-time supporter of apprenticeships and is committed to growing and mentoring talent.

“There are obvious benefits for the apprentice – that wonderful blend of earning and learning, as well as getting hands on experience on exciting projects. Taking on apprentices is an important way to grow the company and nurture talent.”

The new apprentices will be working on a range of projects including high profile contracts such as Southsea Coastal Partnership, Arches and Retaining Wall N22 Road Project and a new Hydroelectric scheme inverness.

Richard Kirk, CEO of Workplus, said, “Moore Concrete has been a member of Workplus since we began in 2015, and they’ve shown a strong commitment to growing the apprenticeship culture in Northern Ireland. It is great to see how they continue to grow their workforce, taking on new apprentices, and helping to equip the next generation of engineers.”

Moore Concrete was established in 1978. Last September, it created 35 new jobs as part of a £700,000 investment in its operations.

Workplus makes it easier for employers to find apprentices by providing a single place for applicants to apply, as well as ensuring a simple, thorough selection process for employers.

The announcement was made during NI Apprenticeship Week – a DfE initiative designed to raise the profile of apprenticeships across Northern Ireland.

Aine Carey, HR Coordinator of Moore Concrete, said, “We are very pleased to be making this positive announcement during Apprenticeship Week. Moore Concrete has been a long-time supporter of apprenticeships and is committed to growing and mentoring talent.

“There are obvious benefits for the apprentice – that wonderful blend of earning and learning, as well as getting hands on experience on exciting projects. Taking on apprentices is an important way to grow the company and nurture talent.”

The new apprentices will be working on a range of projects including high profile contracts such as Southsea Coastal Partnership, Arches and Retaining Wall N22 Road Project and a new Hydroelectric scheme inverness.

Richard Kirk, CEO of Workplus, said, “Moore Concrete has been a member of Workplus since we began in 2015, and they’ve shown a strong commitment to growing the apprenticeship culture in Northern Ireland. It is great to see how they continue to grow their workforce, taking on new apprentices, and helping to equip the next generation of engineers.”

Moore Concrete was established in 1978. Last September, it created 35 new jobs as part of a £700,000 investment in its operations.

Workplus makes it easier for employers to find apprentices by providing a single place for applicants to apply, as well as ensuring a simple, thorough selection process for employers.

10/04/2021

Moore Concrete Virtual Step Challenge from Ballymena to California

Throughout the month of March Moore Concrete took on the Challenge to walk from Ballymena to California (8258km) to help raise money for the Air Ambulance Northern Ireland

We managed to walk a fantastic 12,752,757 steps which equates to 8501.8km (1 km = 1,500 walking steps) so a big well done to everyone who participated and helped us virtually reach California.

So far we have managed to raise an overall total of £1282.80 and its not too late to donate. Our Just Giving page will be open until the end of April.

https://www.justgiving.com/fundraising/mooreconcretesteps

We managed to walk a fantastic 12,752,757 steps which equates to 8501.8km (1 km = 1,500 walking steps) so a big well done to everyone who participated and helped us virtually reach California.

So far we have managed to raise an overall total of £1282.80 and its not too late to donate. Our Just Giving page will be open until the end of April.

https://www.justgiving.com/fundraising/mooreconcretesteps

24/03/2021

Moore Concrete awarded “We Invest In People Gold" Accreditation.

Moore Concrete are delighted to have been awarded the “We Invest In People Gold Accreditation.” An award that only 17% of accredited organisations achieve.

The Investors in People accreditation is recognised all over the world and demonstrates a clear commitment to the people who make up an organisation from Managing Director through to apprentice.

Paul Devoy, CEO of Investors in People, said: “We’d like to congratulate Moore Concrete’s Gold accreditation. It is a fantastic effort for any organisation, and places Moore Concrete in fine company with a host of organisations that understand the value of people.”

Commenting on the award, Managing Director Wilbert Moore said: “Moore Concrete’s greatest strength has always been its people who are at the heart of everything we do.

"I am really proud of the IIP Gold accreditation which has been a direct result of the training, focus, communication and commitment invested by every team member.

"And it doesn’t stop here. Moore Concrete will continue to invest further to improve and develop alongside its people.”

The Investors in People accreditation is recognised all over the world and demonstrates a clear commitment to the people who make up an organisation from Managing Director through to apprentice.

Paul Devoy, CEO of Investors in People, said: “We’d like to congratulate Moore Concrete’s Gold accreditation. It is a fantastic effort for any organisation, and places Moore Concrete in fine company with a host of organisations that understand the value of people.”

Commenting on the award, Managing Director Wilbert Moore said: “Moore Concrete’s greatest strength has always been its people who are at the heart of everything we do.

"I am really proud of the IIP Gold accreditation which has been a direct result of the training, focus, communication and commitment invested by every team member.

"And it doesn’t stop here. Moore Concrete will continue to invest further to improve and develop alongside its people.”

26/11/2020

Major investment at RTU

Ready mixed concrete, mortar and specialist cement screed supplier RTU recently invested in a new workshop facility at its Newtownabbey plant on the outskirts of Belfast. Established 30 years ago, the company has a fast growing customer base throughout the island of Ireland.

The new four bay workshop is due to become operational over the coming weeks. Company Director, Franklin McIlroy takes up the story:

“The facility represents an investment of £200,000. It has a floor area of 504 square metres.”

“He continued:

“We have always been able to service our manufacturing plant on site. But, up to this point, all our lorries and vans were sent off site for servicing.

“This approach can lead to a significant proportion of our transport fleet being out of service at any one time. This has become a greater issue for us, given the ongoing of the expansion of the business.

“The most obvious way to resolve this challenge was to bring all our transport servicing in-house. The new workshop will allow us to do this. It’s an investment that will also create a number of new jobs in our servicing department.”

When it came to the construction of the new workshop, the RTU management team had narrowed the options down to either Prestressed Wall Panels or pouring concrete walls insitu.

Franklin McIlroy commented:

“We decided to go down the prestressed wall panel route, primarily for the speed and ease of installation that panels offered, given they arrive onsite, made to measure and pre-cured. Furthermore, the panels could be installed in all weather conditions which is an advantage given the time of year and our climate.

Ballymena-based Moore Concrete manufactured and installed the prestressed wall panels. The company’s Nicola McAdam was a recent visitor to RTU. She confirmed that a total of 68 panels were supplied in a range of lengths to meet the RTU’s specific requirements.

Nicola commented:

“Our prestressed wall panels are available in a range of heights and thicknesses depending on the application.”

“We were delighted to have the opportunity of working with the RTU team. Prestressed Wall Panels can also be re-sited if required allowing buildings to be adapted in the future, unlike traditional construction methods.”

Franklin McIlroy concluded:

“We were delighted with the level of service provided by Moore Concrete. The panels were manufactured and installed efficiently and within the agreed time frame.”

The new four bay workshop is due to become operational over the coming weeks. Company Director, Franklin McIlroy takes up the story:

“The facility represents an investment of £200,000. It has a floor area of 504 square metres.”

“He continued:

“We have always been able to service our manufacturing plant on site. But, up to this point, all our lorries and vans were sent off site for servicing.

“This approach can lead to a significant proportion of our transport fleet being out of service at any one time. This has become a greater issue for us, given the ongoing of the expansion of the business.

“The most obvious way to resolve this challenge was to bring all our transport servicing in-house. The new workshop will allow us to do this. It’s an investment that will also create a number of new jobs in our servicing department.”

When it came to the construction of the new workshop, the RTU management team had narrowed the options down to either Prestressed Wall Panels or pouring concrete walls insitu.

Franklin McIlroy commented:

“We decided to go down the prestressed wall panel route, primarily for the speed and ease of installation that panels offered, given they arrive onsite, made to measure and pre-cured. Furthermore, the panels could be installed in all weather conditions which is an advantage given the time of year and our climate.

Ballymena-based Moore Concrete manufactured and installed the prestressed wall panels. The company’s Nicola McAdam was a recent visitor to RTU. She confirmed that a total of 68 panels were supplied in a range of lengths to meet the RTU’s specific requirements.

Nicola commented:

“Our prestressed wall panels are available in a range of heights and thicknesses depending on the application.”

“We were delighted to have the opportunity of working with the RTU team. Prestressed Wall Panels can also be re-sited if required allowing buildings to be adapted in the future, unlike traditional construction methods.”

Franklin McIlroy concluded:

“We were delighted with the level of service provided by Moore Concrete. The panels were manufactured and installed efficiently and within the agreed time frame.”

14/10/2020

CONCRETE FIRM ON SOLID GROUND WITH £700,000 INVESTMENT AND CREATION OF 35 JOBS

Moore Concrete, a Ballymena based precast concrete firm, has created 35 new jobs as part of a £700,000 investment in its operations.

The majority of the roles have been put in place since the start of March this year, including positions such as graduate engineers, project management, sales, apprentices in civil engineering and construction management.

With some posts still to fill, the plans will bring the company’s headcount to 158.

When all the posts are in place, they will “strengthen the company’s technical and management capabilities,” according to managing director Wilbert Moore.

The Mid and East Antrim business manufactures a wide range of standard and bespoke products for use across the construction, civil engineering and agriculture sectors across the UK.

The investment comes as the company remained open for business throughout the Covid-19 pandemic, despite production falling by 40% in the immediate aftermath of lockdown.

“Our people have always been our greatest asset,” said Mr Moore.

“During the worst of the pandemic, our aim was to remain open, supporting essential industries including several major infrastructure projects and the wider agricultural sector.

“However, we gradually increased output back to pre-lockdown levels to the point where our manufacturing output is now at the highest levels yet this year. We’re now looking to further enhance our service offering by investing in our technical, commercial, management & production skills base.

“The farming sector is a key part of our business and, as everyone is aware, agriculture has been operating at full capacity throughout the pandemic. This has been reflected in the continuing investment taking place on farms throughout the UK, all of which is causing a wider ripple effect on the sector’s supply chain.

“We have also seen a resurgence in civil engineering and house building activity right across the UK in recent weeks,” he said.

The firm already has a strong foothold in Great Britain, having recently contributed to the development of offshore clean energy farms off the Scottish coastline, a number of coastal protection schemes and rail infrastructure projects in London, but plans to expand its reach further across the UK.

Whilst Mr Moore believes Brexit still presents a level of uncertainty, especially around supply chain elements, he remains optimistic especially as the company sources the “vast majority” of its raw materials locally.

“We welcome the government’s commitment to major infrastructure projects as well as unrestricted access to customers across the UK, Ireland and EU markets in a post-Brexit world,” he continued.

Mr Moore is also a member of the Steering Team of the Manufacturing Task Force, an industry-led initiative established by Mid and East Antrim Borough Council to support and stimulate the manufacturing sector within the borough.

Welcoming the news of the continued investment at the company, Graham Whitehurst, Chair of the Manufacturing Task Force, said:

“With its combination of modern facilities, people skills, design expertise and manufacturing experience, Moore Concrete is another example of a local company that is continuing to play its part in supporting the economy, especially at this challenging time.

“The team has shown over the years how it is committed to meeting the needs of its customers and the growth of its workforce is further proof of that.”

The majority of the roles have been put in place since the start of March this year, including positions such as graduate engineers, project management, sales, apprentices in civil engineering and construction management.

With some posts still to fill, the plans will bring the company’s headcount to 158.

When all the posts are in place, they will “strengthen the company’s technical and management capabilities,” according to managing director Wilbert Moore.

The Mid and East Antrim business manufactures a wide range of standard and bespoke products for use across the construction, civil engineering and agriculture sectors across the UK.

The investment comes as the company remained open for business throughout the Covid-19 pandemic, despite production falling by 40% in the immediate aftermath of lockdown.

“Our people have always been our greatest asset,” said Mr Moore.

“During the worst of the pandemic, our aim was to remain open, supporting essential industries including several major infrastructure projects and the wider agricultural sector.

“However, we gradually increased output back to pre-lockdown levels to the point where our manufacturing output is now at the highest levels yet this year. We’re now looking to further enhance our service offering by investing in our technical, commercial, management & production skills base.

“The farming sector is a key part of our business and, as everyone is aware, agriculture has been operating at full capacity throughout the pandemic. This has been reflected in the continuing investment taking place on farms throughout the UK, all of which is causing a wider ripple effect on the sector’s supply chain.

“We have also seen a resurgence in civil engineering and house building activity right across the UK in recent weeks,” he said.

The firm already has a strong foothold in Great Britain, having recently contributed to the development of offshore clean energy farms off the Scottish coastline, a number of coastal protection schemes and rail infrastructure projects in London, but plans to expand its reach further across the UK.

Whilst Mr Moore believes Brexit still presents a level of uncertainty, especially around supply chain elements, he remains optimistic especially as the company sources the “vast majority” of its raw materials locally.

“We welcome the government’s commitment to major infrastructure projects as well as unrestricted access to customers across the UK, Ireland and EU markets in a post-Brexit world,” he continued.

Mr Moore is also a member of the Steering Team of the Manufacturing Task Force, an industry-led initiative established by Mid and East Antrim Borough Council to support and stimulate the manufacturing sector within the borough.

Welcoming the news of the continued investment at the company, Graham Whitehurst, Chair of the Manufacturing Task Force, said:

“With its combination of modern facilities, people skills, design expertise and manufacturing experience, Moore Concrete is another example of a local company that is continuing to play its part in supporting the economy, especially at this challenging time.

“The team has shown over the years how it is committed to meeting the needs of its customers and the growth of its workforce is further proof of that.”

14/10/2020

Bulk Powder Terminals carries out major warehouse conversion using flexible free standing ‘L’ Retaining Walls and Bunker Walls.

Bulk Powder Terminals based within the Port of Liverpool, is a purpose-built warehouse facility for the import of bulk minerals and chemicals, storage and final distribution to the end user clients.

The terminal specialises in dry bulk chemicals and minerals to service UK clients in the Glass, Detergents, Chemicals, Minerals and the Animal Feed industries.

Bulk Powder Terminals recently purchased 164 4 metre Free Standing “L” Retaining Walls and 59 3.6 metre Bunker Walls as part of a new flexible storage solution for their warehousing.

“Moore Concrete were superb, the product the staff and installation engineers. A credit to the management, and owners and staff. Well Done.” Raj Patel – Managing Director – Newport Industries / Bulk Powder Terminals

The terminal specialises in dry bulk chemicals and minerals to service UK clients in the Glass, Detergents, Chemicals, Minerals and the Animal Feed industries.

Bulk Powder Terminals recently purchased 164 4 metre Free Standing “L” Retaining Walls and 59 3.6 metre Bunker Walls as part of a new flexible storage solution for their warehousing.

“Moore Concrete were superb, the product the staff and installation engineers. A credit to the management, and owners and staff. Well Done.” Raj Patel – Managing Director – Newport Industries / Bulk Powder Terminals

14/10/2020

Fairhaven to Church Scar Coastal Protection Scheme

Following coastal erosion of the 1890’s revetments along the coast of Fylde encompassing Fairhaven lake and Church Scar, Fylde Council in collaboration with the Environment Agency raised funding to allow for the provision of new precast concrete revetments and the revitalisation of promenade and sea front facilities.

Fylde Council required the work to be undertaken area to protect peoples’ homes and sustain economic growth in the area. The combined flood and erosion risk contains 2,600 residential properties, schools and infrastructure serving the wider area.

Moore Concrete were challenged to manufacture over 3300 flat and stepped revetment units and pedestrian access units, amounting to 22,000 Tonnes of concrete in over 40 variations of unit type.

All precast elements are fibre-reinforced with no reinforcing steel. The abrasion resistant concrete mix design was designed to extend the project design life and withstand wave action in the marine environment.

Due to the fast and competent delivery of the Fairhaven to Church Scar Coast Protection Scheme, funding was also released for works at Granny’s Bay during this current construction campaign. Moore Concrete was privileged to continue its work with VBA JV on this phase of the scheme in order to deliver a complete coastal protection scheme for the Fylde Council area.

The Fairhaven and Granny’s Bay phases were completed in Fylde Buff pigmented colour to resemble the golden sand along the Fylde coast. Moore Concrete successfully delivered the precast revetments with a high degree of colour consistency.

In addition to revetments; as part of the Granny’s Bay phase of the works Moore Concrete supplied 176 splash wall seating units to be incorporated into the promenade revitalisation element of the works.

Throughout the duration of the scheme access for transport was is particularly challenging due to the large volume of loads and since on-site storage of units was not possible. The position of each unit on the trailer was planned using daily call-off sheets which enabled 1115 loads were delivered to site on a ‘just in time’ basis. Close working between our dispatch team, our logistics partner and site management ensured site works continued without delay.

Fylde Council required the work to be undertaken area to protect peoples’ homes and sustain economic growth in the area. The combined flood and erosion risk contains 2,600 residential properties, schools and infrastructure serving the wider area.

Moore Concrete were challenged to manufacture over 3300 flat and stepped revetment units and pedestrian access units, amounting to 22,000 Tonnes of concrete in over 40 variations of unit type.

All precast elements are fibre-reinforced with no reinforcing steel. The abrasion resistant concrete mix design was designed to extend the project design life and withstand wave action in the marine environment.

Due to the fast and competent delivery of the Fairhaven to Church Scar Coast Protection Scheme, funding was also released for works at Granny’s Bay during this current construction campaign. Moore Concrete was privileged to continue its work with VBA JV on this phase of the scheme in order to deliver a complete coastal protection scheme for the Fylde Council area.

The Fairhaven and Granny’s Bay phases were completed in Fylde Buff pigmented colour to resemble the golden sand along the Fylde coast. Moore Concrete successfully delivered the precast revetments with a high degree of colour consistency.

In addition to revetments; as part of the Granny’s Bay phase of the works Moore Concrete supplied 176 splash wall seating units to be incorporated into the promenade revitalisation element of the works.

Throughout the duration of the scheme access for transport was is particularly challenging due to the large volume of loads and since on-site storage of units was not possible. The position of each unit on the trailer was planned using daily call-off sheets which enabled 1115 loads were delivered to site on a ‘just in time’ basis. Close working between our dispatch team, our logistics partner and site management ensured site works continued without delay.

14/10/2020

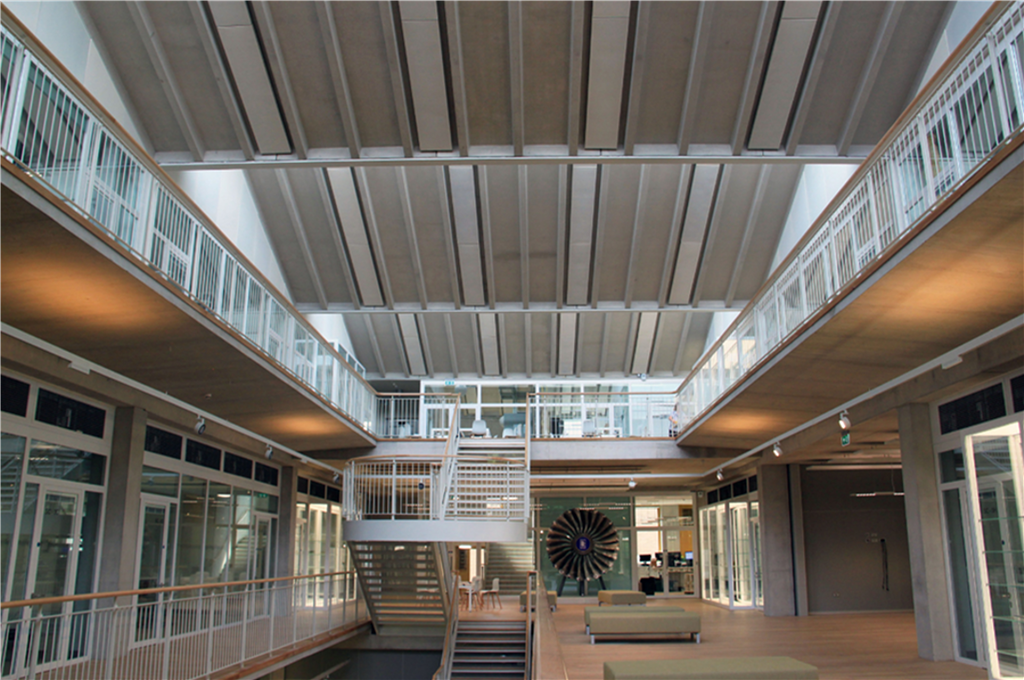

Moore Concrete receive Highly Commended Award for their work within Sevenoaks School

Moore Concrete are proud to have received a Highly Commended Award at the Concrete Society Dinner at the end of last year for their innovative work within the construction of Sevenoaks School.

The school features a precast ribbed roof structure manufactured and installed by Moore Concrete, as the standout feature. It is made up of one hundred and seventeen precast roof slabs comprising of two different designs both requiring a high quality finish and colour consistency.

Project challenges included –

Early stage Involvement with the consultants to achieve agreement on quality targets which would deliver for the design, in terms of finish and appearance. This involved production of numerous samples for comparison and final selection by the architect.

In-depth design involvement including structural analysis, detailing of fixings and steel support bracketry. The scheme design was for a very thin profile panel (75mm), and challenged our engineers in terms of structural performance carrying roof loads, over large spans.

The high-quality finish required was a demanding challenge for all the Moore Concrete team. This meant high attention to detail at all stages of production, storage, transport, and site installation. Careful moulding and de-moulding work produced units with minimal occurrence of corner chipping. Robust protection measures during loading and transportation were required, which was the subject of extensive discussion with the client team, before agreement on approved methods.

Allowance for building services and placing slab connections in relation to structural steelwork resulted in a total of eighty variations across the two hundred and seventeen roof slabs. The correct location of these was highly successful as a result of close cooperation between Moore Concrete and the steelwork subcontractor.

To maintain the high-quality finish, we took painstaking care during offloading of units onsite avoiding damage. A dedicated site installation team thoroughly planned and agreed installation with the Main Contractor ahead of works commencing. Installation carried on uninterrupted within a congested construction site. All members of the project design team have expressed high commendation on our finished product, and successful achievement of the scheme design.

The school features a precast ribbed roof structure manufactured and installed by Moore Concrete, as the standout feature. It is made up of one hundred and seventeen precast roof slabs comprising of two different designs both requiring a high quality finish and colour consistency.

Project challenges included –

Early stage Involvement with the consultants to achieve agreement on quality targets which would deliver for the design, in terms of finish and appearance. This involved production of numerous samples for comparison and final selection by the architect.

In-depth design involvement including structural analysis, detailing of fixings and steel support bracketry. The scheme design was for a very thin profile panel (75mm), and challenged our engineers in terms of structural performance carrying roof loads, over large spans.

The high-quality finish required was a demanding challenge for all the Moore Concrete team. This meant high attention to detail at all stages of production, storage, transport, and site installation. Careful moulding and de-moulding work produced units with minimal occurrence of corner chipping. Robust protection measures during loading and transportation were required, which was the subject of extensive discussion with the client team, before agreement on approved methods.

Allowance for building services and placing slab connections in relation to structural steelwork resulted in a total of eighty variations across the two hundred and seventeen roof slabs. The correct location of these was highly successful as a result of close cooperation between Moore Concrete and the steelwork subcontractor.

To maintain the high-quality finish, we took painstaking care during offloading of units onsite avoiding damage. A dedicated site installation team thoroughly planned and agreed installation with the Main Contractor ahead of works commencing. Installation carried on uninterrupted within a congested construction site. All members of the project design team have expressed high commendation on our finished product, and successful achievement of the scheme design.

14/10/2020

Moore Concrete receives ministerial visit

Moore Concrete receives ministerial visit

Minister of State at the Northern Ireland Office, Robin Walker MP, recently visited Moore Concrete. He was accompanied by the Mayor of Mid and East Antrim Borough Council, Councillor Peter Johnston, and the Deputy Mayor, Councillor Andrew Wilson.

The Ballymena based precast concrete operation manufactures a wide range of standard and bespoke products for use in the civil engineering, agriculture and construction sectors throughout the UK. The company employs 150 people and, last year, generated a turnover of just over £12m.

The Minister’s visit allowed him to gauge, at first-hand, how Moore Concrete is coping with the Covid-19 pandemic. The company has remained open for business throughout the crisis. Robin Walker met members of the Moore Concrete management team and was given a tour of the manufacturing site.

Moore Concrete managing director Wilbert Moore commented:

“Our primary objective has been to ensure the health and safety our staff. Every possible step has been taken to ensure that social distancing and all other relevant Covid-19 preventative measures have been in place since the onset of the pandemic.”

“These included the use of the furlough scheme and encouraging staff to work from home, where possible.

“We formed a Business Continuity team with representatives from departments across Moore Concrete at the start of March, reviewing government guidance, engaging with employees and adjusting our approach as the situation developed. Working together was essential in navigating the ever changing landscape.

He continued:

“Our aim was to remain open if possible, supporting essential industries including several major infrastructure projects and the agricultural sector, fulfilling our commitment to customers, with an overriding emphasis on the protection our employees. Immediately post lockdown production fell by 40%. However, over the next few months we have gradually increased output back to pre-lockdown volumes.

“Manufacturing output is, currently, at the highest levels achieved this year. Furloughed staff have returned, and overall employment is up 12% from the start of March. We are currently actively recruiting for additional positions.

“We have seen a resurgence in civil engineering and house building activity across the UK over recent weeks.

“The farming sector accounts a very significant proportion of our turnover. As everyone will be aware, agriculture has been operating at full throttle throughout the pandemic. This has been reflected in the continuing investment taking place on farms throughout the UK.”

Commenting on the future prospects for his business, Wilbert Moore focussed on the upcoming challenge of Brexit. He said:

“With the majority of our products sold in GB it is imperative that there are no restrictions placed on trade between Northern Ireland and the rest of the UK.

“We also need to see continuing and consistent investment by government in infrastructure, agriculture and housing.”

Minister Walker expressed his delight at having the opportunity to visit Moore Concrete. He commented:

"My visit to Moore Concrete was a good opportunity to hear about the issues experienced by the company and the wider construction sector during Covid 19.”

"I was pleased to be able to visit the firm's Ballymena premises, to learn about the value of UK Government support and to hear how Moore Concrete made great strides in ensuring they remained open for business while always keeping health and safety at the forefront of their minds. “

"The UK Government will continue to work collaboratively with businesses, the Northern Ireland Executive and local partners to get the economy back up and running, laying the foundations for a stable and sustainable economic future."

Minister of State at the Northern Ireland Office, Robin Walker MP, recently visited Moore Concrete. He was accompanied by the Mayor of Mid and East Antrim Borough Council, Councillor Peter Johnston, and the Deputy Mayor, Councillor Andrew Wilson.

The Ballymena based precast concrete operation manufactures a wide range of standard and bespoke products for use in the civil engineering, agriculture and construction sectors throughout the UK. The company employs 150 people and, last year, generated a turnover of just over £12m.

The Minister’s visit allowed him to gauge, at first-hand, how Moore Concrete is coping with the Covid-19 pandemic. The company has remained open for business throughout the crisis. Robin Walker met members of the Moore Concrete management team and was given a tour of the manufacturing site.

Moore Concrete managing director Wilbert Moore commented:

“Our primary objective has been to ensure the health and safety our staff. Every possible step has been taken to ensure that social distancing and all other relevant Covid-19 preventative measures have been in place since the onset of the pandemic.”

“These included the use of the furlough scheme and encouraging staff to work from home, where possible.

“We formed a Business Continuity team with representatives from departments across Moore Concrete at the start of March, reviewing government guidance, engaging with employees and adjusting our approach as the situation developed. Working together was essential in navigating the ever changing landscape.

He continued:

“Our aim was to remain open if possible, supporting essential industries including several major infrastructure projects and the agricultural sector, fulfilling our commitment to customers, with an overriding emphasis on the protection our employees. Immediately post lockdown production fell by 40%. However, over the next few months we have gradually increased output back to pre-lockdown volumes.

“Manufacturing output is, currently, at the highest levels achieved this year. Furloughed staff have returned, and overall employment is up 12% from the start of March. We are currently actively recruiting for additional positions.

“We have seen a resurgence in civil engineering and house building activity across the UK over recent weeks.

“The farming sector accounts a very significant proportion of our turnover. As everyone will be aware, agriculture has been operating at full throttle throughout the pandemic. This has been reflected in the continuing investment taking place on farms throughout the UK.”

Commenting on the future prospects for his business, Wilbert Moore focussed on the upcoming challenge of Brexit. He said:

“With the majority of our products sold in GB it is imperative that there are no restrictions placed on trade between Northern Ireland and the rest of the UK.

“We also need to see continuing and consistent investment by government in infrastructure, agriculture and housing.”

Minister Walker expressed his delight at having the opportunity to visit Moore Concrete. He commented:

"My visit to Moore Concrete was a good opportunity to hear about the issues experienced by the company and the wider construction sector during Covid 19.”

"I was pleased to be able to visit the firm's Ballymena premises, to learn about the value of UK Government support and to hear how Moore Concrete made great strides in ensuring they remained open for business while always keeping health and safety at the forefront of their minds. “

"The UK Government will continue to work collaboratively with businesses, the Northern Ireland Executive and local partners to get the economy back up and running, laying the foundations for a stable and sustainable economic future."

13/09/2017

Moore Concrete Bunker Walls provide the flexible grain storage option

The Kane family grow just over 900ac of combinable crops and grass near Seaforde in Co Down. This year’s enterprise mix comprises winter barley, winter wheat, winter oilseed rape, food grade oats and spring barley. Also included is a smaller acreage of grass ley, which is used to produce silage and hay.

“The winter barley harvest is now complete,” Richard Kane confirmed.

“We grew 250ac of 6-row varieties, including Volume. Yields are down a bit on last year. I put this down to the very dry spell that we had in June. But the performance of the crops was still more than acceptable.

He added:

“The policy on the farm is to dry and store all the grain we produce. This allows us to service feed compounders the year round.

“Thankfully, we have seen a rise in cereal prices in line with the recent devaluation of Sterling against the Euro. Strong prices for straw represent another bonus. This contrasts completely with the situation a couple of years ago when demand for straw was very weak and prices were on the floor.

Richard’s business model brings with it a requirement for high quality storage facilities.

He said:

“Back in 2009, we built a specifically designed store with a capacity to hold 4,500 tonne of grain. But we also needed a system that was sufficiently flexible to allow us to segregate the different cereals grown on the farm.

“At the time we looked at a number of options, including grain bins and bespoke silos. However, we quickly recognised that the most efficient way of meeting our needs was to put the dried cereals onto a concrete floor and then use the bunker walls, manufactured by Moore Concrete, to provide the segregation we required.

“We now have 50 of the precast wall units in the store. Each is free standing but sufficiently heavy to maintain grains in place, even when loaded from the one side only.

“Total storage flexibility is achieved courtesy of each unit being easily moved from one location to another within the store using a forklift, thanks to the built in fork recesses.”

Moore Concrete’s Jeff Haslett was a recent visitor to the Kane Farm. He confirmed the growing demand for the bunker wall system within the arable sector.

“Cereal growers recognise the total flexibility which the system offers, when it comes to storing grain,” he said.

“Each unit is 3m (10’) high and weighs 2.7 tonne, although we manufacture walls up to 4.3m (14’).

“The unique curved shape of the base was designed to allow the free flow of material to the floor.

“There is a 100mm (4’) straight portion at the bottom edge, where the wall meets the floor, to aid the removal of material from the bay.”

Jeff added:

Walls up to 3m in height do not need bolted down when retaining material such as grain, solid fuels, recycling materials, wood chip, potatoes etc.

For further information, telephone Moore Concrete on (028) 2565 2566 Ext 1 or view our website at www.moore-concrete.com.

“The winter barley harvest is now complete,” Richard Kane confirmed.

“We grew 250ac of 6-row varieties, including Volume. Yields are down a bit on last year. I put this down to the very dry spell that we had in June. But the performance of the crops was still more than acceptable.

He added:

“The policy on the farm is to dry and store all the grain we produce. This allows us to service feed compounders the year round.

“Thankfully, we have seen a rise in cereal prices in line with the recent devaluation of Sterling against the Euro. Strong prices for straw represent another bonus. This contrasts completely with the situation a couple of years ago when demand for straw was very weak and prices were on the floor.

Richard’s business model brings with it a requirement for high quality storage facilities.

He said:

“Back in 2009, we built a specifically designed store with a capacity to hold 4,500 tonne of grain. But we also needed a system that was sufficiently flexible to allow us to segregate the different cereals grown on the farm.

“At the time we looked at a number of options, including grain bins and bespoke silos. However, we quickly recognised that the most efficient way of meeting our needs was to put the dried cereals onto a concrete floor and then use the bunker walls, manufactured by Moore Concrete, to provide the segregation we required.

“We now have 50 of the precast wall units in the store. Each is free standing but sufficiently heavy to maintain grains in place, even when loaded from the one side only.

“Total storage flexibility is achieved courtesy of each unit being easily moved from one location to another within the store using a forklift, thanks to the built in fork recesses.”

Moore Concrete’s Jeff Haslett was a recent visitor to the Kane Farm. He confirmed the growing demand for the bunker wall system within the arable sector.

“Cereal growers recognise the total flexibility which the system offers, when it comes to storing grain,” he said.

“Each unit is 3m (10’) high and weighs 2.7 tonne, although we manufacture walls up to 4.3m (14’).

“The unique curved shape of the base was designed to allow the free flow of material to the floor.

“There is a 100mm (4’) straight portion at the bottom edge, where the wall meets the floor, to aid the removal of material from the bay.”

Jeff added:

Walls up to 3m in height do not need bolted down when retaining material such as grain, solid fuels, recycling materials, wood chip, potatoes etc.

For further information, telephone Moore Concrete on (028) 2565 2566 Ext 1 or view our website at www.moore-concrete.com.

13/09/2017

Concrete Panel Hurling wall proves ‘big hit’ with Ruairí Óg youth teams

Hurling walls are helping to improve the skill levels of young players immeasurably, according to Padraig Groogan, the trainer of the current Ruairí Óg CLG ‘Under 14’ team in Cushendall.

“We invested in the wall almost two years ago. And it is allowing the players hone their skills the year round,” he said.

“They can practise as a team or as individuals. The accompanying flood lights make it possible for the players to practise well into the evening, winter and summer. The ball is always coming back to the players, which means that they can get in the maximum number of touches, catches and strikes within a prescribed period of time.

“So, in a way, the wall becomes their coach.”

He adds:

“Hurling is one of the most skilful games in the world. And hurling walls are helping players of all ages hone the skills they need to an extremely high level. But, above all else, the players get tremendous enjoyment from using the wall.

“The wall is 40m long and 5m high. Each player needs around 2m of space to use the wall. This means that we have ample space for a group of 20, during a team training session.”

Broughshane-based Moore Concrete was selected to manufacture and erect the hurling wall on site: it comprises 32 separate precast concrete panels. The company’s Jeff Haslett takes up the story.

“We manufacture a comprehensive range of panelled wall systems, for use in buildings, silos and, of course hurling walls. We have erected numerous walls for clubs up to this point, including Lavey, Leitrim & Ballygalget” he said.

“The big advantage of using precast panels is the fact that walls can be erected on site, within hours of the panels arriving.

“We are happy to provide a turnkey service, from design through to the actual construction on-site.”

Lottery funding is available for hurling walls. All relevant information can be found by visiting the website: http://www.lottery.culture.gov.uk

For further information, contact Moore Concrete on (028) 2565 2566

“We invested in the wall almost two years ago. And it is allowing the players hone their skills the year round,” he said.

“They can practise as a team or as individuals. The accompanying flood lights make it possible for the players to practise well into the evening, winter and summer. The ball is always coming back to the players, which means that they can get in the maximum number of touches, catches and strikes within a prescribed period of time.

“So, in a way, the wall becomes their coach.”

He adds:

“Hurling is one of the most skilful games in the world. And hurling walls are helping players of all ages hone the skills they need to an extremely high level. But, above all else, the players get tremendous enjoyment from using the wall.

“The wall is 40m long and 5m high. Each player needs around 2m of space to use the wall. This means that we have ample space for a group of 20, during a team training session.”

Broughshane-based Moore Concrete was selected to manufacture and erect the hurling wall on site: it comprises 32 separate precast concrete panels. The company’s Jeff Haslett takes up the story.

“We manufacture a comprehensive range of panelled wall systems, for use in buildings, silos and, of course hurling walls. We have erected numerous walls for clubs up to this point, including Lavey, Leitrim & Ballygalget” he said.

“The big advantage of using precast panels is the fact that walls can be erected on site, within hours of the panels arriving.

“We are happy to provide a turnkey service, from design through to the actual construction on-site.”

Lottery funding is available for hurling walls. All relevant information can be found by visiting the website: http://www.lottery.culture.gov.uk

For further information, contact Moore Concrete on (028) 2565 2566

13/09/2017

Textured Concrete Facade Panels show cased in unique London restoration project

A bespoke extension to the gate lodge of Richmond Park Estate at Henley-on Thames is testimony to the unique architectural, engineering and precasting skills now available in Northern Ireland. The privately owned Warren Cottage is a landmark location in the Coombe Wood conservation area of London.

Back in 2012, the team at Kilrea-based McGarry-Moon architects were commissioned to renovate the then dilapidated cottage into a new family home. The end result comprised a total overhaul of the existing structure plus the development of a 176m2 extension. A separate 72m2 garden room was also included in the project brief.

“Our brief was to make what was already on site into a functional family home while adding to the character and heritage of the original building,” confirmed principal architect Steven Moon.

“The project was completed last July, following a two-year construction phase. Our design for the extension centred on the optimal use of glass, in order to capture the maximum amount of light, plus the use of bespoke board marked concrete wall panels.”

According to Steven board-marked concrete is the name for a process of patterning concrete that leaves a wood grain image on the finished face of the concrete. It is a method of construction that is being used more frequently these days because concrete is extremely well-suited as a finished material in modern design, and by imprinting the wood grain on the surface, it visually softens and warms concrete’s somewhat cooler appearance while still allowing concrete to express the construction technique.

“But we did not want to be adding the board marked effect on site. The alternative is to use wall panels that have been made in specific board marked moulds.”

“We had previously worked with the team at Moore Concrete on a number of previous projects. So an initial call was made to Broughshane, to gauge the feasibility of having the Warren Cottage panels fabricated at the company’s factory.”

“I am happy to confirm that the answer secured can be best summarised as a resounding ‘yes’.

According to Steven, there followed an intense period of liaison between the architects involved on the Warren Cottage and the structural engineers at Moore Concrete. This process led to the securing of final agreement on the specification of the wall panels and the actual moulds that should be used.

“Bespoke projects of this nature are very much part and parcel of the service that we offer clients,” confirmed Moore Concrete sales’ manager Richard Whiteside.

“We have our own team of highly specialised structural engineers and designers, who are available to work with architects and the complete range of other clients.

“Precast concrete is fast being recognised as one of the most versatile building products that is now available to architects and designers.

“In the first instance, it allows a high proportion of the structural work associated with any building project to be completed to an exemplary standard off

Back in 2012, the team at Kilrea-based McGarry-Moon architects were commissioned to renovate the then dilapidated cottage into a new family home. The end result comprised a total overhaul of the existing structure plus the development of a 176m2 extension. A separate 72m2 garden room was also included in the project brief.

“Our brief was to make what was already on site into a functional family home while adding to the character and heritage of the original building,” confirmed principal architect Steven Moon.

“The project was completed last July, following a two-year construction phase. Our design for the extension centred on the optimal use of glass, in order to capture the maximum amount of light, plus the use of bespoke board marked concrete wall panels.”

According to Steven board-marked concrete is the name for a process of patterning concrete that leaves a wood grain image on the finished face of the concrete. It is a method of construction that is being used more frequently these days because concrete is extremely well-suited as a finished material in modern design, and by imprinting the wood grain on the surface, it visually softens and warms concrete’s somewhat cooler appearance while still allowing concrete to express the construction technique.

“But we did not want to be adding the board marked effect on site. The alternative is to use wall panels that have been made in specific board marked moulds.”

“We had previously worked with the team at Moore Concrete on a number of previous projects. So an initial call was made to Broughshane, to gauge the feasibility of having the Warren Cottage panels fabricated at the company’s factory.”

“I am happy to confirm that the answer secured can be best summarised as a resounding ‘yes’.

According to Steven, there followed an intense period of liaison between the architects involved on the Warren Cottage and the structural engineers at Moore Concrete. This process led to the securing of final agreement on the specification of the wall panels and the actual moulds that should be used.

“Bespoke projects of this nature are very much part and parcel of the service that we offer clients,” confirmed Moore Concrete sales’ manager Richard Whiteside.

“We have our own team of highly specialised structural engineers and designers, who are available to work with architects and the complete range of other clients.

“Precast concrete is fast being recognised as one of the most versatile building products that is now available to architects and designers.

“In the first instance, it allows a high proportion of the structural work associated with any building project to be completed to an exemplary standard off

13/09/2017

Hydro Power - Precast Concrete Perfect Solution

The Scottish Government is committed to making Scotland a Hydro Nation. It recognises that the country’s water resource is significant and, in a world demanding more food and water, there is good reason to nurture it for long term sustainable use.

Accordingly, water is of fundamental importance for Scotland’s economy, health, social wellbeing and environment. It is universally recognised that the hydro-economy provides huge opportunities for Scotland. This will be achieved through the economic development and good stewardship of Scotland’s abundant water resources.

The Scottish Government has agreed to support the development of the country’s hydro economy and the enormous potential that this brings. And, in this context, three main drivers have been identified.

The first of these is the utilisation of Scottish expertise to maximise the economic benefit of abundant water resources within a sound ecological context. This will be achieved by reducing energy use, improving efficiency and creating a low carbon water nation. Secondly, Scotland will raise its international profile as an international leader on water management and governance: in other words the country will become the first Hydro. Overarching these core objectives will be the development of a water centre of expertise and research with international reach.

For its part Green Highland Renewables has been developing a number of run-of-river hydro schemes since 2007. These have been developed in partnership with a number of ‘blue chip’ organisations, such as the Forestry Commission Scotland. However, the company – which has offices in Perth and Dingwall – has also made a significant investment commitment of its own to the economy of the Highlands’ region. Up to the end of September this year, the business committed £55 million towards an ambitious build programme.

Moreover, the company is on-track to commission ten new hydro schemes across the north of Scotland in the coming months. This brings the company’s total investment since 2010 to over £117 million – the majority of which has been spent in the Highlands’ region.

“We have a full order book for 2017 with more than £40 million planned investment in the pipeline,” says Green Highland Renewables’ Chief Executive Officer Mark Mathieson.

“It is a very exciting place to be, and we are continually innovating in terms of how we deliver schemes. The majority of spend in hydro goes on civil construction, and for us the lion’s share goes to local building firms and contractors,” Mathieson says.

The hydro development service offered by Green Highland Renewables is turn-key in nature: from initial concept through to consent, construction, commissioning and generation. The company has extensive in-house capability covering planning, development, civil, mechanical and electrical engineering.

April of 2016 was marked by Green Highland Renewables starting work on two run-of-river hydro schemes in Glen Affric . The projects, c

Accordingly, water is of fundamental importance for Scotland’s economy, health, social wellbeing and environment. It is universally recognised that the hydro-economy provides huge opportunities for Scotland. This will be achieved through the economic development and good stewardship of Scotland’s abundant water resources.

The Scottish Government has agreed to support the development of the country’s hydro economy and the enormous potential that this brings. And, in this context, three main drivers have been identified.

The first of these is the utilisation of Scottish expertise to maximise the economic benefit of abundant water resources within a sound ecological context. This will be achieved by reducing energy use, improving efficiency and creating a low carbon water nation. Secondly, Scotland will raise its international profile as an international leader on water management and governance: in other words the country will become the first Hydro. Overarching these core objectives will be the development of a water centre of expertise and research with international reach.

For its part Green Highland Renewables has been developing a number of run-of-river hydro schemes since 2007. These have been developed in partnership with a number of ‘blue chip’ organisations, such as the Forestry Commission Scotland. However, the company – which has offices in Perth and Dingwall – has also made a significant investment commitment of its own to the economy of the Highlands’ region. Up to the end of September this year, the business committed £55 million towards an ambitious build programme.

Moreover, the company is on-track to commission ten new hydro schemes across the north of Scotland in the coming months. This brings the company’s total investment since 2010 to over £117 million – the majority of which has been spent in the Highlands’ region.

“We have a full order book for 2017 with more than £40 million planned investment in the pipeline,” says Green Highland Renewables’ Chief Executive Officer Mark Mathieson.

“It is a very exciting place to be, and we are continually innovating in terms of how we deliver schemes. The majority of spend in hydro goes on civil construction, and for us the lion’s share goes to local building firms and contractors,” Mathieson says.

The hydro development service offered by Green Highland Renewables is turn-key in nature: from initial concept through to consent, construction, commissioning and generation. The company has extensive in-house capability covering planning, development, civil, mechanical and electrical engineering.

April of 2016 was marked by Green Highland Renewables starting work on two run-of-river hydro schemes in Glen Affric . The projects, c

13/09/2017

Induce natural growth without elaborate soil or watering systems using ECOncrete® Bio Active Living Wall.

Urban sprawl calls for innovative green solutions that reduce the ecological footprint of concrete based infrastructure. Typical green roofs or green walls systems usually demand elaborate soil and watering system, however this is not the case in ECOncrete® Bio Active concrete wall tile design, that has a bio-enhanced substrate that supports the growth of mosses, lichens and climbing vegetation and doubles as a highly aesthetic decorate façade.

The innovative ECOncrete®Bio Active wall tiles differ from standard concrete units on three levels; concrete chemistry, surface rugosity and 3D macro complexity. These three elements work in synergy to mimic the features of natural surfaces thus enhancing the walls ability to support rich flora of plants that require little or no soil. ECOncrete®’s unique Bio Active wall mix is tailored to keep the pH of water encountering the surface low, as opposed to the highly alkaline pH of water accumulated on standard concrete. The high surface rugosity, and the unique 3D design includes micro pores, rugged textures, and varying elevations, increase the walls ability to capture water and moisture, thus further contributing to flora growth as well as increasing their ability to effectively latch onto the wall surface.

ECOncrete®Bio Active wall tiles were used in the construction of a biological pond and fountain at the BIG commercial centre (Ashdod Israel). This installation demonstrated the ability of the tiles to receive rich and diverse foliage, mimicking natural waterfall/spring plant life in an urban setting.

For additional information please see www.moore-concrete.com or contract us directly at Moore Concrete Products Ltd on 028 2565 2566 or by email at info@moore-concrete.com.

The innovative ECOncrete®Bio Active wall tiles differ from standard concrete units on three levels; concrete chemistry, surface rugosity and 3D macro complexity. These three elements work in synergy to mimic the features of natural surfaces thus enhancing the walls ability to support rich flora of plants that require little or no soil. ECOncrete®’s unique Bio Active wall mix is tailored to keep the pH of water encountering the surface low, as opposed to the highly alkaline pH of water accumulated on standard concrete. The high surface rugosity, and the unique 3D design includes micro pores, rugged textures, and varying elevations, increase the walls ability to capture water and moisture, thus further contributing to flora growth as well as increasing their ability to effectively latch onto the wall surface.

ECOncrete®Bio Active wall tiles were used in the construction of a biological pond and fountain at the BIG commercial centre (Ashdod Israel). This installation demonstrated the ability of the tiles to receive rich and diverse foliage, mimicking natural waterfall/spring plant life in an urban setting.

For additional information please see www.moore-concrete.com or contract us directly at Moore Concrete Products Ltd on 028 2565 2566 or by email at info@moore-concrete.com.

13/09/2017

ECOncrete® Bio Active Living Wall Decreasing the Ecological Footprint of Urban Development

ECOncrete®’s Bio-Active Wall Installation at the Azouri Eco-Tower (Tel Aviv, Israel) contributed to the buildings LEED innovation points and was the first Israeli office building to receive a Gold LEED certificate. LEED is a global standard rating system for Leadership in Energy and Environmental Design, to evaluate the environmental performance of a building and encourage market transformation towards sustainable design. On this project approximately a month after planting, the wall started developing noticeable plant coverage. As little as three months post planting mosses started colonising the wall, covering between a few centimetres to over half the tile surface in certain cases. Based on research findings from this project and other prior installations ECOncrete®’s has been able to evaluate its role in deceasing the ecological footprint of urban environment by;

• Promoting high plant diversity and coverage on the structures façade

• Contributing to air quality through oxygen production of enhanced plant coverage

• Increasing energy efficiency of the structures envelope

• Absorption and reduction of atmospheric CO2

• Acting as a passive acoustic insulation

• Enhanced foliage cover serves to absorb solar radiation

• High foliage cover captures pollutants from the air

• Increasing the overall aesthetics of the structure.

Standard and pocket tiles are 30cm’s square, although dimensions can be adjusted to meet the needs of specific projects.

For additional information please see www.moore-concrete.com or contract us directly at Moore Concrete Products Ltd on 028 2565 2566 or by email at info@moore-concrete.com.

• Promoting high plant diversity and coverage on the structures façade

• Contributing to air quality through oxygen production of enhanced plant coverage

• Increasing energy efficiency of the structures envelope

• Absorption and reduction of atmospheric CO2

• Acting as a passive acoustic insulation

• Enhanced foliage cover serves to absorb solar radiation

• High foliage cover captures pollutants from the air

• Increasing the overall aesthetics of the structure.

Standard and pocket tiles are 30cm’s square, although dimensions can be adjusted to meet the needs of specific projects.

For additional information please see www.moore-concrete.com or contract us directly at Moore Concrete Products Ltd on 028 2565 2566 or by email at info@moore-concrete.com.

13/09/2017

Milford on Sea Concrete Beach Huts